Press release

Robust recycling technology for a sustainable future

carboliq GmbH will be presenting its innovative chemical recycling technology at this year’s K trade fair in Düsseldorf (8–15 October, Hall 6, Stand D76). As part of the joint stand of the Ministry of Economic Affairs, Small Business, Climate Protection and Energy of the State of North Rhine-Westphalia, the company will explain how plastic waste can be turned back into valuable resources – efficiently, environmentally friendly and in a forward-looking manner.

A process that sets standards

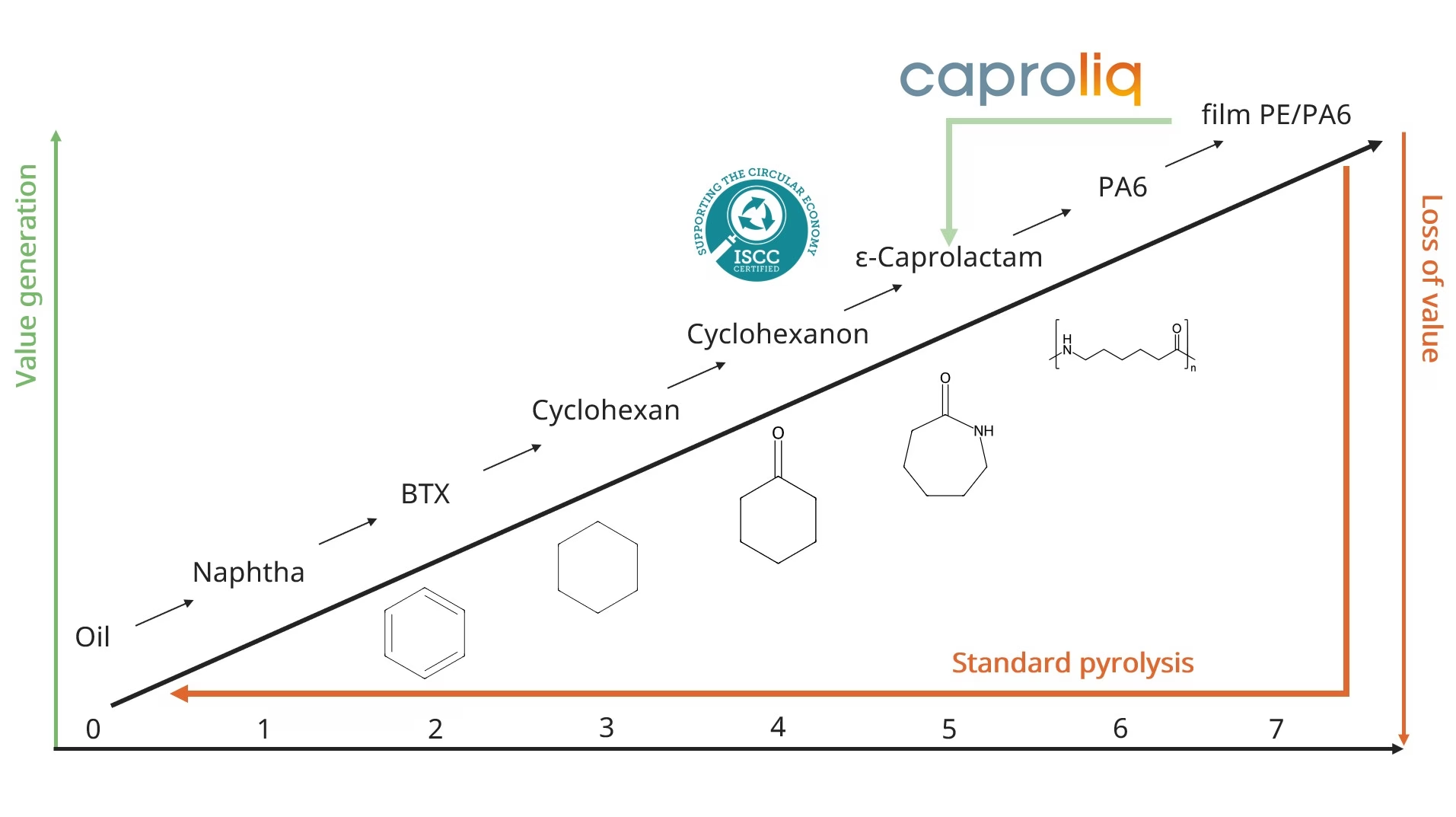

The carboliq process is a single-stage, thermal-catalytic process for liquefying solid hydrocarbons. It enables the recovery of high-quality liquid raw materials – known as circular liquid resources (CLR) – from mixed and contaminated plastic waste. carboliq thus offers a genuine alternative to thermal recycling.

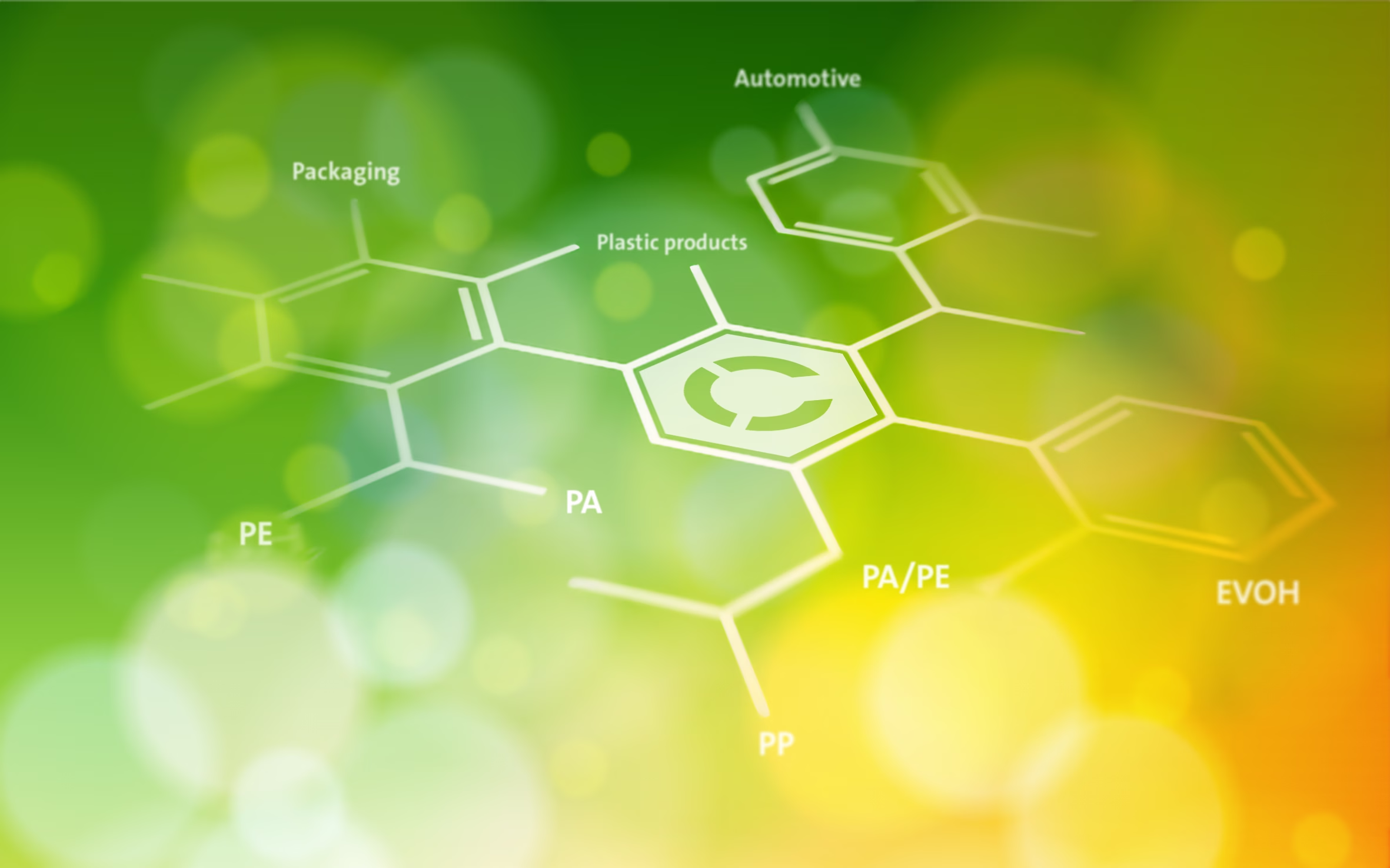

When processing plastics containing PA6, the complex component caprolactam can also be isolated and reprocessed into polyamide. This results in considerable savings in the manufacturing process, as the monomer, which is costly to produce, can be used directly, thus helping to conserve fossil resources. ‘Our goal is to promote the circular economy in the plastics industry and enable all participants in the value chain to achieve the recycling quotas and climate protection targets that have been set,’ says Dr Harald Klein, Managing Director of carboliq.

Robust, flexible, economical

One outstanding feature of carboliq technology is its robustness when it comes to different input materials. Whether it’s single-type plastics from the automotive or fast fashion industries, mixed packaging waste or heavily contaminated fractions, the process handles them reliably and efficiently. This flexibility makes carboliq particularly attractive for local authorities, waste disposal companies and industrial partners looking for scalable solutions for plastic streams that are difficult to recycle.

Pollutant elimination for high-quality recyclates

Ein weiterer Vorteil: Während des Prozesses werden Schadstoffe aus dem Material entfernt. Das Ergebnis sind Rezyklate, die höchsten Qualitätsanforderungen genügen und sich für anspruchsvolle Anwendungen eignen – da die daraus hergestellten Kunststoffe Neuwarenqualität haben. Damit leistet carboliq einen wichtigen Beitrag zur Schließung des Kunststoffkreislaufs und zur Reduktion von Umweltbelastungen.

Conserving resources through circular economy

In view of increasingly scarce fossil raw materials and growing environmental problems caused by plastic waste, returning plastics to the recycling cycle is more urgent than ever. The carboliq process enables precisely that: it breaks down plastics into their basic chemical components and returns them to the production cycle – without losses in waste incineration and with a significantly lower carbon footprint.

Carboliq sees itself as a complementary partner to mechanical recycling, stepping in where mechanical recycling reaches its limits. ‘We offer companies tailor-made solutions for their plastic waste to develop circular business models and replace fossil raw materials,’ explains Dr Klein.

carboliq at the K trade fair 2025

Interested visitors can find out more about the capabilities of carboliq technology in person at the K trade fair in Düsseldorf. Experts will be available for discussions at stand D76 in hall 6, the joint stand of the North Rhine-Westphalia Ministry of Economic Affairs, and will provide insights into current projects, research plans and the strategic development of the process. In addition, Christian Haupts, founder of carboliq GmbH, will take part in a Circular Valley panel discussion on 14 October at 1:15 p.m. in Hall 6, Stand C40, where chemical recycling will be examined from different perspectives.

Further information can be found on our new website at www.carboliq.com.

About carboliq

carboliq was founded in 2017 by Recenso GmbH, an engineering firm, as a technology platform for chemical recycling. The team led by Olivier Inhoff and Christian Haupts has been committed to the design and implementation of raw material recovery systems since 2004. Founded as a spin-off of a long-established German plant engineering company, they develop and implement solutions for the growing demand for secondary raw materials. Both Recenso and carboliq are based in Remscheid – a city with a rich industrial history and close ties to science, skilled workers and suppliers. From there, they operate all over the world. SÜDPACK has been the majority shareholder of carboliq since the beginning of 2024.

carboliq entwickelt, baut und betreibt Anlagen zur Verölung gemischter und kontaminierter Kunststoffabfälle. Das so hergestellte Produkt (CLR – Circular Liquid Ressource) wird von der Petrochemie stark nachgefragt. Es wird zur Herstellung neuer, hochwertiger Polymere einsetzt. Darüber hinaus sind alle Arten von Anwendungen denkbar, aus denen Produkte entstehen, die bislang auf Basis fossiler Rohstoffe hergestellt werden.

With its innovative technology, carboliq closes the carbon cycle, replaces fossil raw materials and actively contributes to reducing climate change. This makes the transformation to circular value creation possible for the plastics industry as well.

Further information is available at www.carboliq.com

Company contact

SÜDPACK

Cordula Schmidt / Company communications

Jägerstrasse 23

D-88416 Ochsenhausen

Tel.: +49 (0) 7352 925 – 1869

cordula.schmidt@suedpack.com

Press contact

REDAKON

Vera Sebastian

Nördliche Auffahrtsallee 25

D-80638 München

Tel.: +49 (0) 89 31 20 338-21

vera.sebastian@redakon.com