Material evaluation

Analyzing plastic waste and optimizing the circular economy

Material evaluation

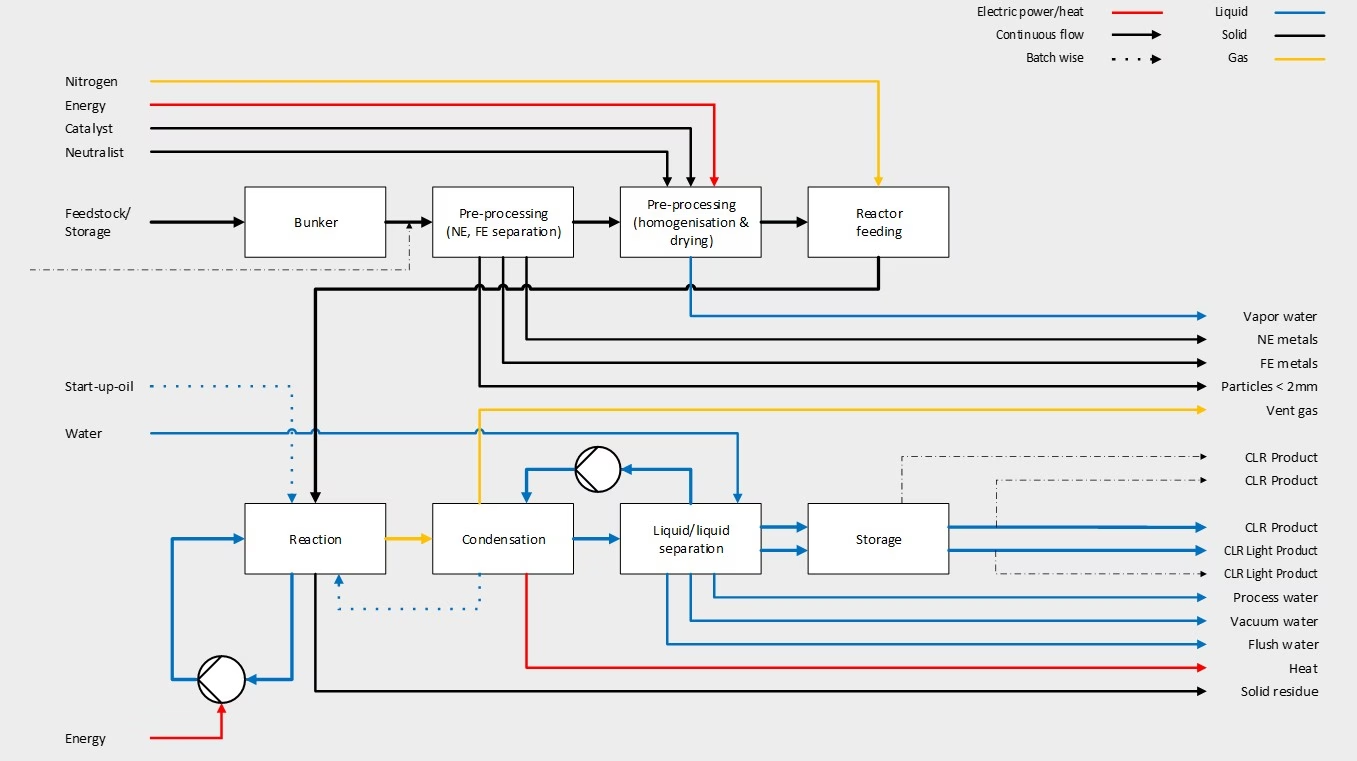

Our material evaluation provides companies with a practical way to assess the potential of the carboliq process. We work with you to develop a closed-loop model tailored to your business model and sustainability goals. We work with you to develop a closed-loop model tailored to your business model and sustainability goals.

We analyze which products are generated during the liquefaction of your plastic waste.

We assess how efficiently these waste materials can be converted, and verify the recoverable quantities. Our material evaluation offers a practical foundation for determining whether the carboliq process is suitable for your specific waste streams.

By leveraging both our extensive expertise and our strong partner network spanning the entire value chain, we develop closed-loop models precisely tailored to your operations. Our goal is to deliver a sustainable solution that is a perfect fit for your business.

Real-world examples from our test campaigns

SÜDPACK is one of the leading manufacturers of high-performance films for the packaging industry. The company’s multi-layer films have already been successfully liquefied in innovative projects. Film waste from dual systems and municipal waste has also proven to be very well suited for the process.

While these materials were unsuitable for mechanical recycling, chemical recycling enabled the recovery of high-quality recyclates for use in the production of new plastics.