CLR® & caproliq®

Our Products

Sustainable feedstock alternatives for the chemical industry

Both CLR® and caproliq® can be used in existing chemical industry infrastructure, making it possible to transition from fossil-based to circular feedstocks without the need for new investments in processing plants.

During the initial phase, blending CLR or caproliq with existing feedstocks is often the preferred approach. Depending on the quality requirements, upgrading and/or the removal of specific impurities may also be appropriate. In any case, the use of carboliq products promotes independence from imported fossil resources.

✔ Avoids oil drilling and fossil fuel exploration

✔ Domestic sources reduce transport distances and associated risks

✔ Decreases dependence on fossil-based resources—and on those who control them

Circular Liquid Resource (CLR®)

The circular liquid resource (CLR) produced from post-consumer plastics using the carboliq process is a direct substitute for fossil hydrocarbons and can be processed using existing refinery and petrochemical infrastructure. This CLR is fully miscible with fossil-based oils and meets the same storage requirements.

Use of CLR

The final product has a boiling range of approximately 60 °C to 550 °C. The distribution is largely determined by the feedstock. When separated via distillation, the lighter fraction (< 280 °C) can generally be used as a direct substitute for naphtha in steam crackers to produce base chemicals for polymer manufacturing, while the heavier fraction can be used directly in wax production.

Demand from the chemical industry far exceeds current supply.

CLR can also be used for energy recovery, serving as a secondary fuel to reduce the consumption of primary resources.

However, since its use as a fuel does not meet the legal definition of “recycling,” the oil produced by carboliq is currently only sold to users who utilize it for material (non-energetic) purposes.

That said, there is significant global interest in its use for energy recovery.

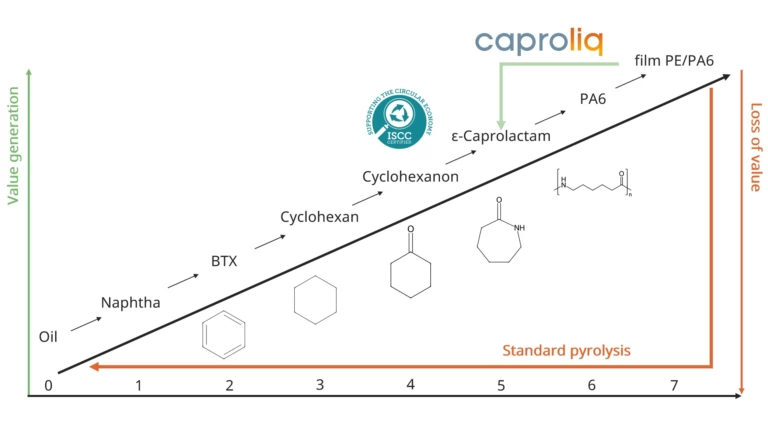

caproliq®

When processing PA6-containing plastic waste, the by-product caprolactam can also be directly recovered.

Using recovered caprolactam for R-PA6 production generates substantial CO2 savings by eliminating the need for energy-intensive monomer synthesis.

High product quality for various feedstock

The process ensures consistent oil quality for various waste streams with a high degree of mixing of different materials and other contamination. Long residence times and the carboliq reaction mixer achieve particularly intensive mixing. This transforms inhomogeneous waste into a homogeneous oil that can be returned to chemical processes as a universal secondary resource.