Press release

Evolution of classic plastic pyrolysis

Reconomy-PA – Evolution from classic plastic pyrolysis to the value-adding concept of the recycling refinery

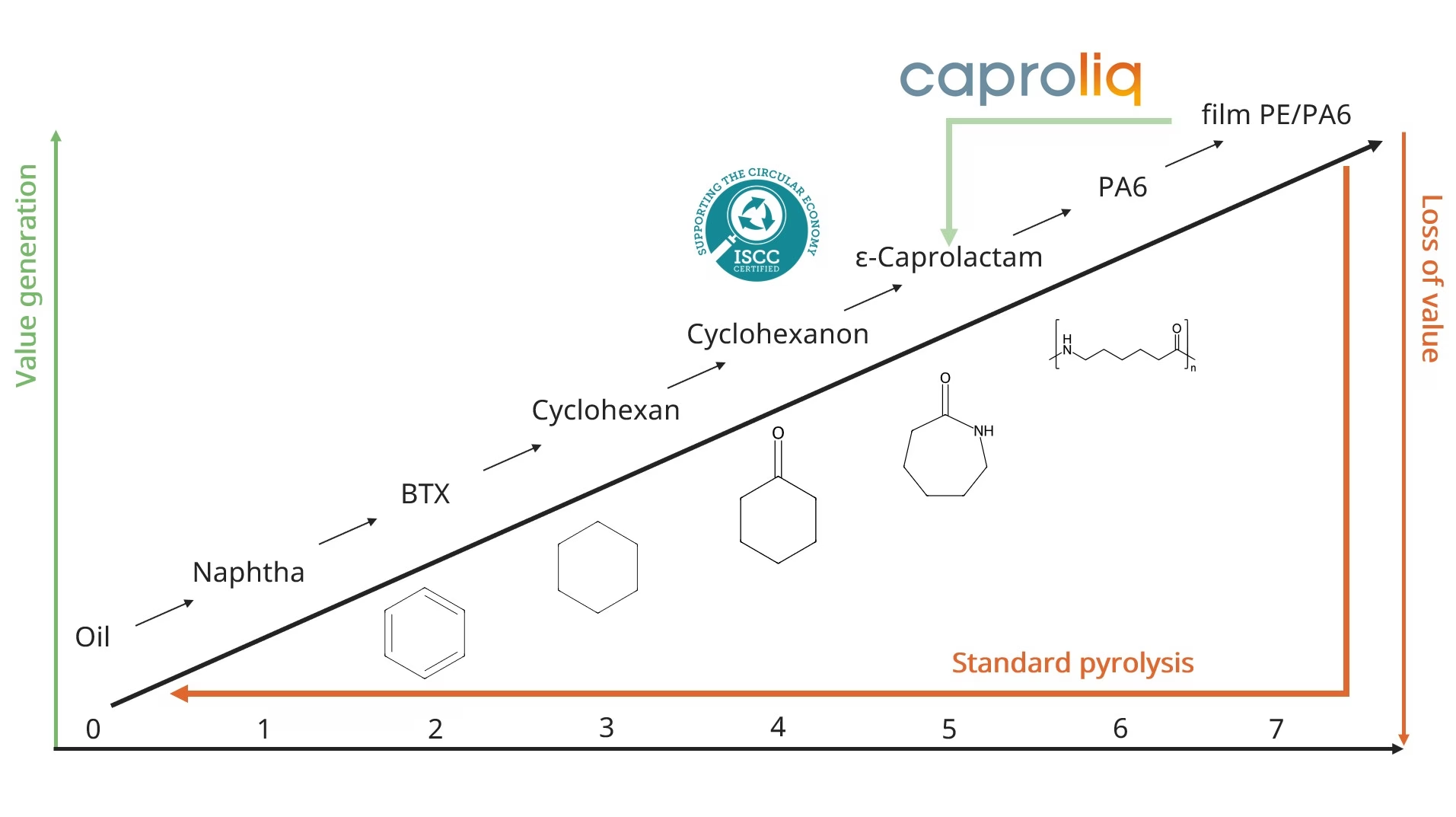

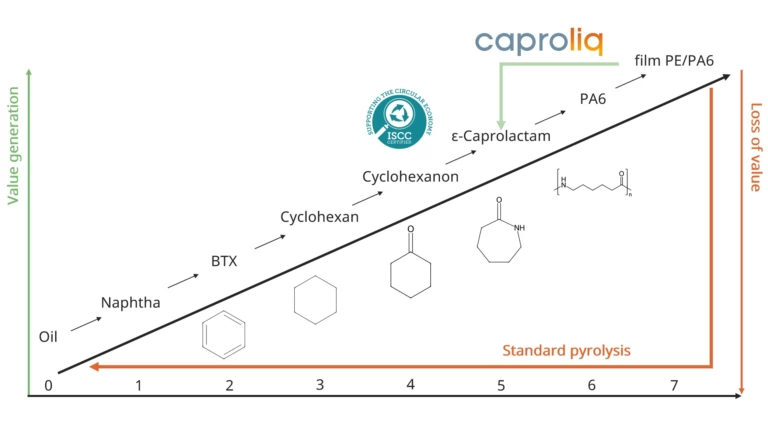

During the pyrolysis of plastics, the polymers are broken down into low-molecular hydrocarbons (pyrolysis oils) and returned to the chemical industry as raw materials. The aim of the project is to use the direct liquefaction of carboliq to produce not only pyrolysis oil but also higher-value co-products, to separate these from the process and to utilise them as products in a later stage of the chemical value chain.

The recovery of caprolactam from PA-6 from mixed plastic waste, primarily from multilayer films, has already been tested in practice, with several hundred tonnes of PA-rich feedstock already processed at carboliq’s pilot plant in Ennigerloh, recovering caprolactam as a co-product. Further potential technical optimisations and related effects in terms of the sustainability of the process and PA recycling are now being investigated by carboliq.

In the second round of submissions for the Industrie.IN.NRW innovation competition, the Reconomy-PA project was accepted into the funding programme and is now co-financed by the European Union and the Ministry of Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia.

Project participants

- carboliq GmbH, Remscheid

- Institute for Applied Polymer Chemistry, Aachen University of Applied Sciences

- Chair of Responsible Process Engineering, Ruhr University Bochum

- Anton Ledwon Engineering Office, Troisdorf