The carboliq process

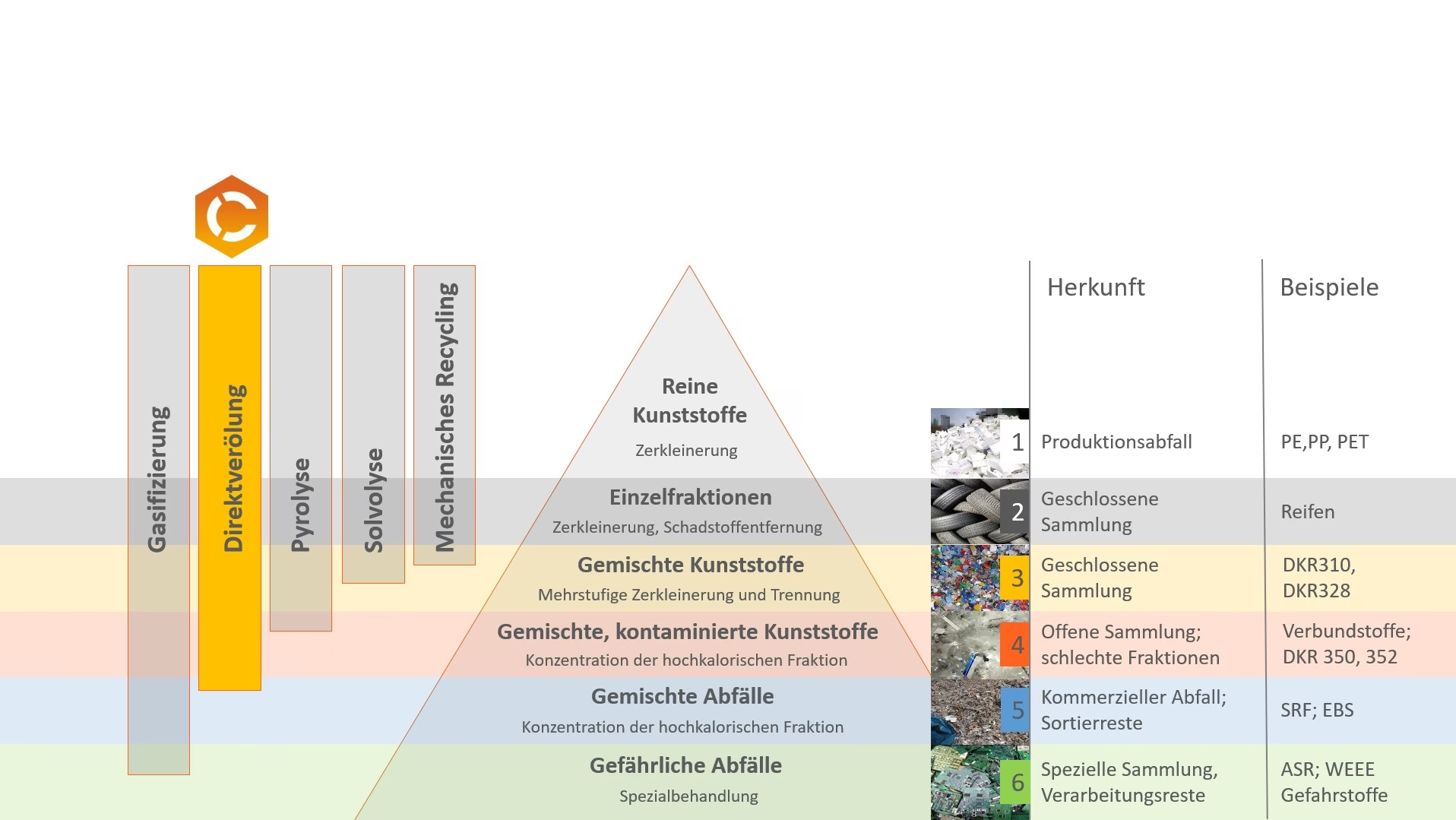

carboliq recovers raw materials that cannot be obtained through mechanical recycling.

carboliq recovers raw materials that mechanical recycling cannot reach

The innovative carboliq technology facilitates a thermochemical recycling process that breaks down plastic waste into its basic components, which are then separated into usable building blocks.

Since most plastics are derived from crude oil, the resulting product is once again a liquid. For this reason, the carboliq process is also referred to as direct oiling or direct liquefaction. carboliq makes it possible to recover raw materials from waste that cannot be processed through mechanical recycling.

Key technology for the circular economy

Chemical recycling is a central component of a sustainable circular economy. Our technology makes it possible to break down plastic waste into its original chemical components – even in heavily contaminated or mixed plastic streams that are unsuitable for mechanical recycling. In this way, we are laying the foundation for genuine recycling at the raw material level and reducing dependence on fossil resources.

carboliq is efficient and climate neutral

The carboliq process is an advanced thermo-chemical recycling method. Liquefaction of the input material takes place in a single process step. At temperatures below 400 °C and under slight vacuum, polymer chains are broken down with the aid of a specialized catalyst. Once the chains are sufficiently shortened, the material is vaporized and then condensed. These conditions enable a high yield of liquid output.

carboliq’s approach to energy input is unique within the field of recycling technology. The reactor contents are heated using electrically driven friction turbines. Friction and shear forces ensure uniform heating while simultaneously achieving high mixing efficiency. This unique concept allows the system to maintain stable reaction conditions by giving different feedstocks the residence time they need for optimal conversion. When powered by renewable electricity, the carboliq process meets the criteria for a truly net-zero technology.

carboliq is not pyrolysis

Compared to other plastic recycling processes, direct liquefaction is increasingly being distinguished from pyrolysis. Breaking down (cracking) plastic molecules in the liquid phase at moderate temperatures leads to higher yields of liquid output and enables continuous operation.

Most pyrolysis processes use wall heating and operate at temperatures well above 400 °C. By contrast, the carboliq process runs at substantially lower temperatures. By combining thermal, catalytic, and mechanochemical mechanisms, polymers are broken down under comparatively mild process conditions. This makes the carboliq process significantly more flexible when it comes to the composition of input materials. In addition, the relatively low operating temperature minimizes coking and prevents the formation of toxic gases such as dioxins and furans. Whereas most pyrolysis technologies require high proportions of polyolefins (such as PE, PP, and PS) in the feedstock, carboliq can also process plastics containing significant proportions of PA (polyamide) and PET (polyethylene terephthalate), as well as mixed and contaminated plastic waste.

carboliq is proven in practice and has a high level of technological readiness

At the waste management center in Ennigerloh, in the Münsterland region of Germany, carboliq operates a pilot plant in partnership with the municipal waste management company ECOWEST Entsorgungsverbund Westfalen GmbH. The plant was purpose-built to process refuse-derived fuels (RDF) generated at ECOWEST’s mechanical-biological treatment facility from commercial waste, post-sorting residuals, and household refuse. These RDFs are used as fuel in cement kilns and combined heat and power (CHP) plants.

CARBOWEST, the operating company, is a certified waste management specialist authorized to accept and process waste. The oiling plant is officially classified as a waste treatment facility and is licensed for continuous operation under the German Federal Emissions Control Act (BImSchG).

To date, the pilot plant has been operated continuously (24/7) for over 22,000 hours. During this time, multiple campaigns have been conducted to liquefy mixed and contaminated plastic waste from a range of sources. The acquired data enables precise calculation of mass, material, and energy balances.

In 2023, experts from the German Environment Agency (UBA) oversaw several campaigns and verified the accuracy of the balance data. The facility is now classified as “qualified with verified operational capability” (TRL 8).

Advantages of carboliq technology

- Robust, mature technology (TRL 8)

- Single-step, continuous production process

- Process temperature below 400 °C

- Atmospheric pressure

- Broad compatibility with various carbon-based raw materials

- High liquid yield with minimal gas formation

- Purely electrical energy input

- Net-zero technology when powered by “green electricity”

- Catalyst used as the only additional consumable